I am a strong believer in thigh supported driving, in all my modern cars it is almost a guarantee that the seat bottom back is as low as I can comfortably sit and the front is lifted to its maximum. My wife hates it, luckily seat memory is a thing these days.

I had long ago purchased the previously available riser kit that was put together years ago by another enthusiast and many Z3 owners have been running to this day. It wasn’t until Bimmerforums member Fumanchu282 posted about his floor failure, in this thread Caution: Seat Tilt Mod Failure, that I had put much more thought into the setup. While the job of getting the front of the seat lifted is accomplished and significantly more comfortable, the engineering side of me never liked the fact that contact between the seat frame and body of the car was reduced to the mating face of the coupling nut. That added with the raising of the seat angle added a cyclical fatigue moment on the stud in the sheet metal floor which eventually ripped out for Fumanchu282. While this failure is not common, I expect more to occur as the age of these installations mature.

I set out with the help of local Z3 head Randy Wilson to design and develop a Double Bee Garage variant of the seat riser mod.

These are a 4 piece design consisting of: 4140 alloy steel bases, 4140 lower tapered washer, 4140 upper tapered rectangular washer and a pair of low profile M8 bolts (Grade 10.9). All parts will come with a black oxide coating for corrosion resistance.

The key design features of the DBG kits include:

Largest car to riser footprint (50mm vs 13mm of the original coupling nut kit)

High grade Alloy steel material (Grade 4140)

Industry standard thread engagement (1.5x thread diameters) at both the upper and lower joint for maximum clamping force

Taper washers ensure maximum contact between the seat frame and lift kit to minimize flex and movement

Largest possible cross section through the seat frame to resist shear forces in the event of unexpected G-forces

Highest lift (30.27MM at the centerline of the fasteners) with the maximized cross section without interfering with rear seat bolt engagement

All parts come black oxide coated for corrosion resistance

4140 alloy steel is a chromium-, molybdenum-, and manganese-containing low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength

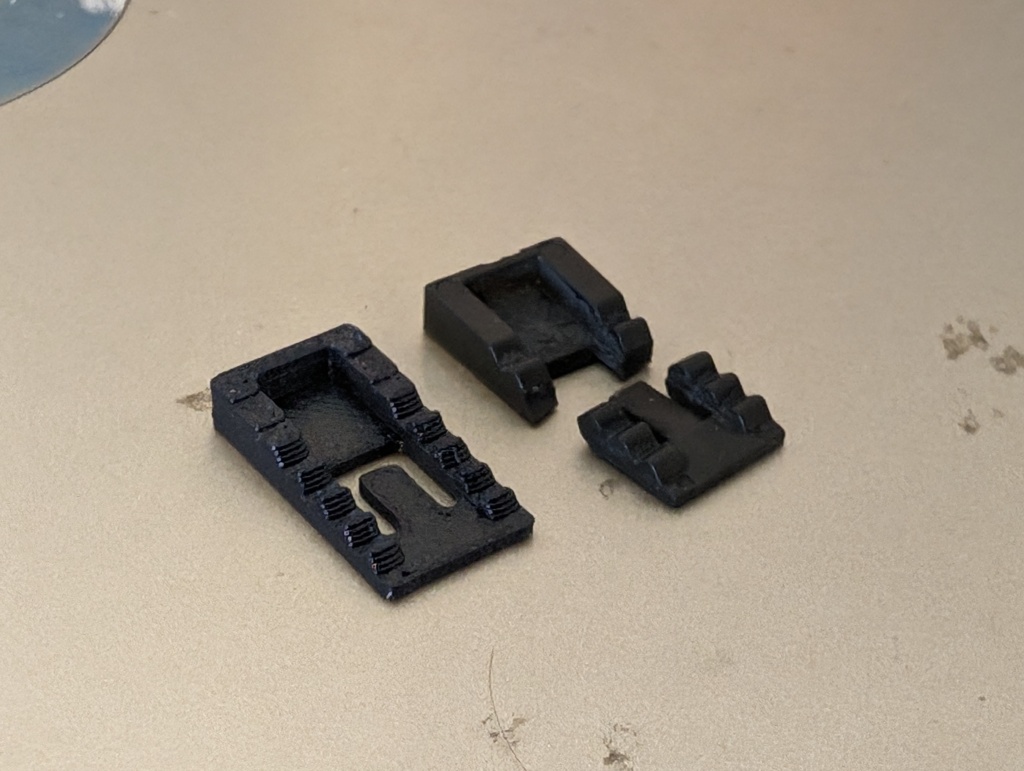

I did a rapid prototype on my 3D printer to verify fitment checks. These install under the carpet to maximize the footprint contact with the floor of the car which is easily accessible when the seats are removed for installation.

This is very close to what the final parts will look like installed, except I didn’t have low profile bolts in the parts drawer. The bolt head grabbed and spun for the test fit plastic washer in the photo below.

Here is the original lift of the other kit that is available:

The final revision vary slightly from the 3D printed variants based on the 3D print fits in the following ways:

1)The base of the mount was reduced from 60mm (pictured) to 50mm due to the cost associated to the larger base material and machining time to design dimensions. I did multiple versions of the base mount and the costs to value ratio was optimized at 50mm.

2)The upper taper washer was changed to a rectangular cross section to ensure the taper surface is properly aligned during assembly. I found that during Prototype fitment that the top washer would rotate (as shown in the pictures above) when the clamping force was applied by the bolt. To remove this rotation, the top washer cross section to fit the seat frame base ensures the taper is aligned with the seat angle to ensure proper clamping force 360 degrees around the joint.

The base threads tightly to the floor structure and has a wide footprint to distribute loads, there are wrench flats on the base to allow for firm torquing to the chassis installed stud. The taper washers maximize clamping forces on the seat frame perpendicular to the bolt threads to ensure even bite to reduce as much flexure at this joint as possible. The head of the bolt is low profile to ensure clearance to the seat slider mechanisms when operated. This does leave a minor angle on the M10 fastener at the rear of the seat frame, but well within an ASTM F606 wedge tensile test criteria expected for the Class 10.9 Factory bolt. That is also considering the frame does not flex at all when the M10 is torqued.

Pricing is $100 PER seat (+tax)

Shipping is a flat rate $20 for up to 4 seats sets within the contiguous US. I will ship worldwide at additional costs.

Each Seat Kit will contain the following which will be for ONE seat:

2x Seat Riser Bases

2x Lower Taper Washer

2x Upper Rectangular Taper Washer

2x M8 Low Profile Bolts

If you wanted to see the installation instructions there are HERE

You can order through PayPal check out by:

Clicking this LINK , or scanning the QR code.

If not contiguous US (international or AK/HI) please use the contact form below.

Leave a comment